Screw Press Machines

1. What is a Screw Press Machine?

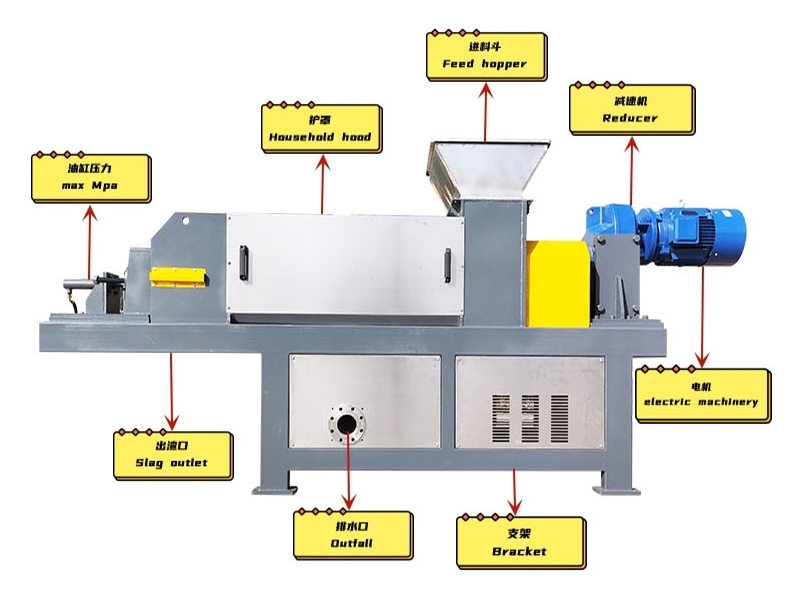

A screw press machine utilizes a rotating screw mechanism to apply continuous mechanical pressure for material separation, dewatering, or extraction. Its core components include a feed hopper, screw shaft, screen mesh, and discharge ports. This technology is widely adopted in wastewater treatment (sludge dewatering), food processing (juice extraction), and offering high efficiency with low energy consumption.

2. Top 5 Industrial Applications of Screw Press Machines

2.1 Sludge Dewatering in Wastewater Treatment

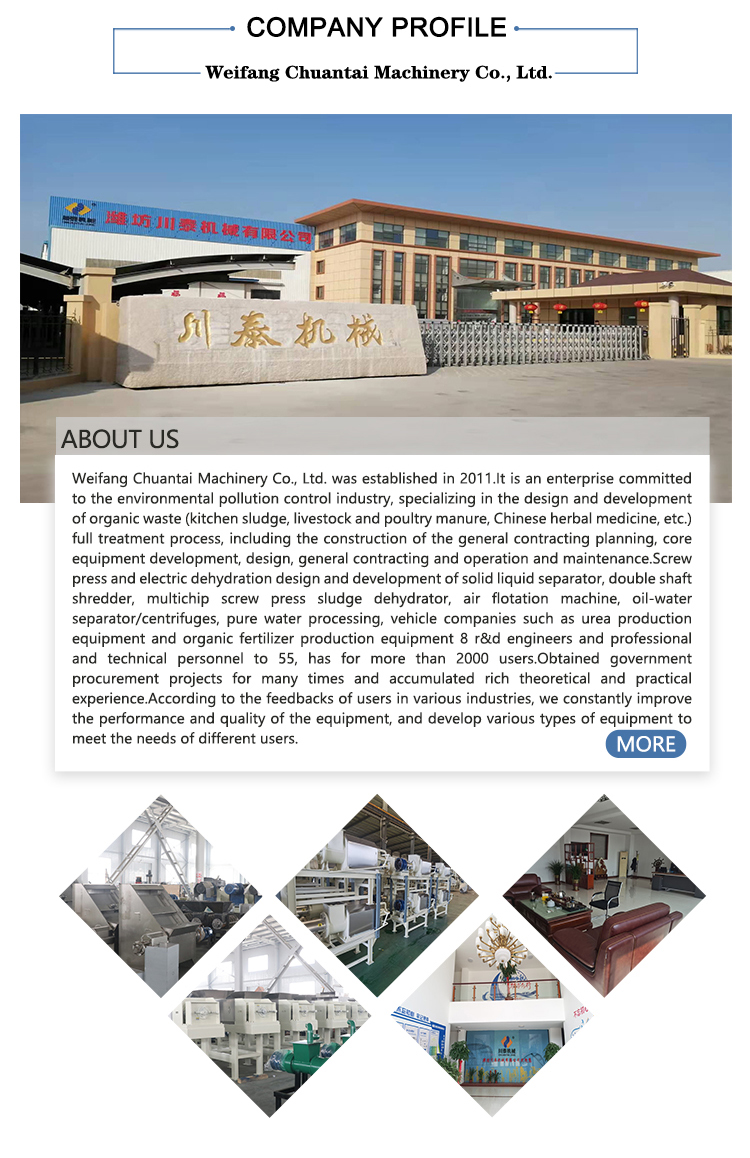

Screw presses reduce sludge volume by 60-80%, critical for municipal and industrial plants. For example, Chuantai Machinery’s systems integrate screw dehydrators and solid-liquid separators to achieve 95% dryness, significantly cutting disposal costs.

2.2 Food Processing: Juice & Pulp Separation

High-capacity screw presses extract juice from fruits/vegetables (e.g., kiwi, apples) at rates up to 20 tons/day, while separating pulp for byproduct utilization.

2.3 Biodiesel Production

Screw presses efficiently crush jatropha and rapeseed, achieving 90% oil recovery for biofuel refineries.

2.4 Agricultural Waste Management

They dewater crop residues (corn stalks, tea leaves) for animal feed or compost production, aligning with circular economy trends.

3. How to Choose the Right Screw Press Machine

3.1 Capacity & Scale

Small-Scale (<15 tons/day): Opt for compact models like the YZS series (ideal for startups).

Large-Scale (>15 tons/day): Choose heavy-duty systems with pre-press functions.

3.2 Material Compatibility

Verify screw pitch and screen size match your raw material’s viscosity. For oily seeds, select models with self-cleaning screens to prevent clogging.

3.3 Energy Efficiency

Variable frequency drives (VFD) in modern machines,860−3,860−4,000 models) reduce power consumption by 30%.

3.4 Post-Sales Support

Prioritize suppliers offering global technical assistance, like GEMCO’s CE-certified warranties.

4. Maintenance Strategies to Extend Equipment Lifespan

4.1 Daily Operations

Lubrication: Use food-grade grease for oil presses; synthetic oils suit high-temperature sludge systems.

Cleaning: Flush residues after each shift to prevent microbial growth (critical in food processing).

4.2Component Replacement Schedule

| Part | Replacement Interval |

|---|---|

| Screw Shaft | 5,000-8,000 hours |

| Filter Screens | 6-12 months |

| Hydraulic Seals | 2 years |

4.3 Downtime Reduction

Implement IoT sensors to monitor parameters like bearing temperature and pressure spikes, enabling predictive maintenance.

5. Future Trends & Innovations

AI-Driven Optimization: Real-time adjustment of screw speed based on material viscosity.

Sustainability Focus: Integration with solar power systems .

Modular Designs: Plug-and-play components for rapid field upgrades.

Conclusion

Screw press machines are pivotal across industries requiring efficient material processing. By selecting models tailored to operational needs and adhering to maintenance protocols, businesses can achieve ROI within 12-18 months.

If your company wants to establish a business relationship with us, please briefly describe the cooperation intention and send an email to:chuantaiscrewpress@gmail.com

![[list:title]](/static/upload/image/20240528/1716877114510915.jpg)