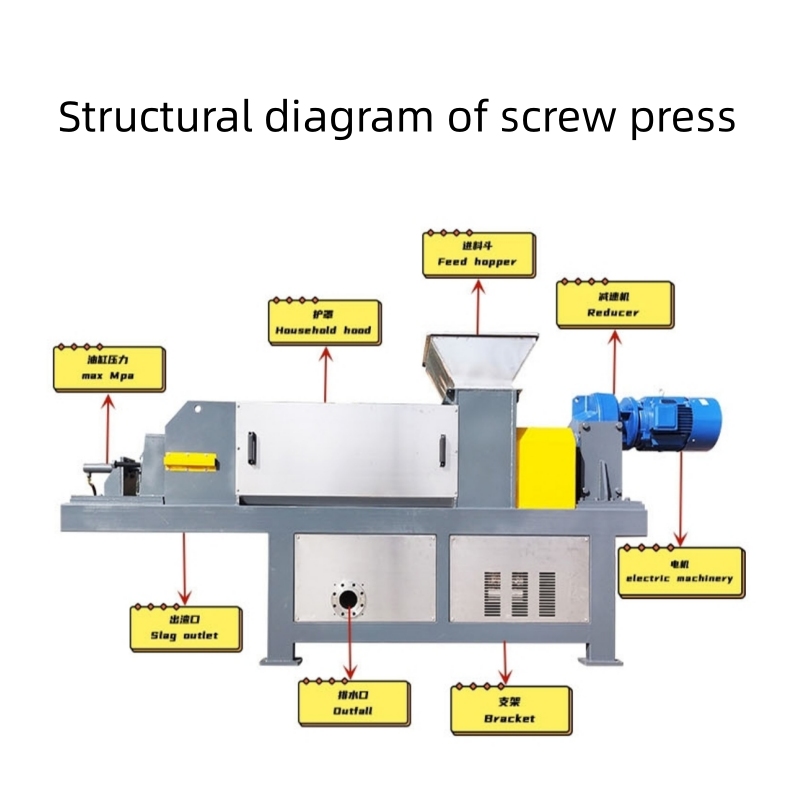

The screw press dehydrator is designed based on the principle of superposition compression. It mainly relies on the cooperation of the feed box, screw, screen and tail cone to achieve the purpose of material juicing and dehydration. The material to be processed is evenly transported to the feed port of the juicer dehydrator through a pump or screw and other tools. After being squeezed by the spiral blades and filtered by the screen, the water or juice flows through the screen to the water receiving tray under the machine and is collected and taken away through the pipeline. The residue after juicing and dehydration is transported to the designated place through the conveyor belt.

Applicable industries

Solid-liquid separation of solid or liquid materials in various industries and squeezing and dehydration of waste residues.

1. Juicing of fruits and vegetables, roots, stems, leaves, flowers, fruits and other materials.

Such as apples, pears, ginger, grapes, alfalfa, pineapple, peach, mulberry, blueberry, pure sea buckthorn fruit, orange, wolfberry, etc.; chrysanthemum, peony, rose and other flowers; beets, red fruit, Jerusalem artichoke, aloe, palm, olive, pomegranate, etc.;

2. Food processing: carrot peels, potato residues, mushrooms, glutinous rice wine lees, seafood waste, onion residues, winter melon residues, bean sprout waste residues, citrus comprehensive utilization, beet residues, Jerusalem artichokes, oil residues, coconut bran, various tea residues, vinegar residues, beer dregs, coffee extraction waste residues, corn husks, furfural residues, fish paste, shrimp residues, chicken feathers and chicken residues, etc.; soy protein, pectin, xanthan gum, etc.;

3. Biopharmaceuticals: extrusion separation of Chinese medicine residues after extraction of granules, powders, etc.; extrusion dehydration of various plant Chinese medicine residues.

4. Energy/fertilizer: biogas residue, sweet sorghum, water hyacinth, cassava residue, sweet potato residue, sugarcane residue, seaweed, waste oil residue, crop residue, wine lees pressing and dehydration, etc.

5. Pressing and dehydration of fruit and vegetable waste, kitchen waste, and domestic waste; separation of food waste, organic matter and inorganic matter;

6. Dehydration of various feces, such as pig manure, cow manure, duck manure, etc., and pressing and separation of slaughterhouse sewage;

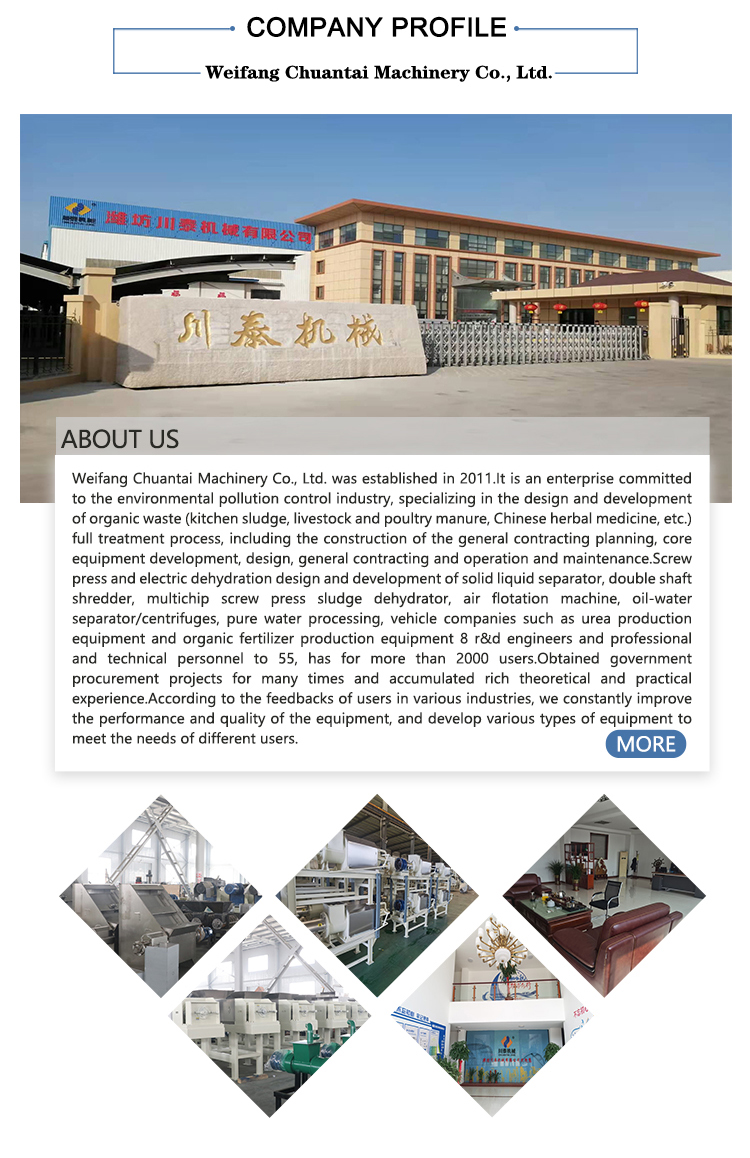

If your company wants to establish a business relationship with us, please briefly describe the cooperation intention and send an email to:chuantaiscrewpress@gmail.com

![[list:title]](/static/upload/image/20240528/1716877114510915.jpg)