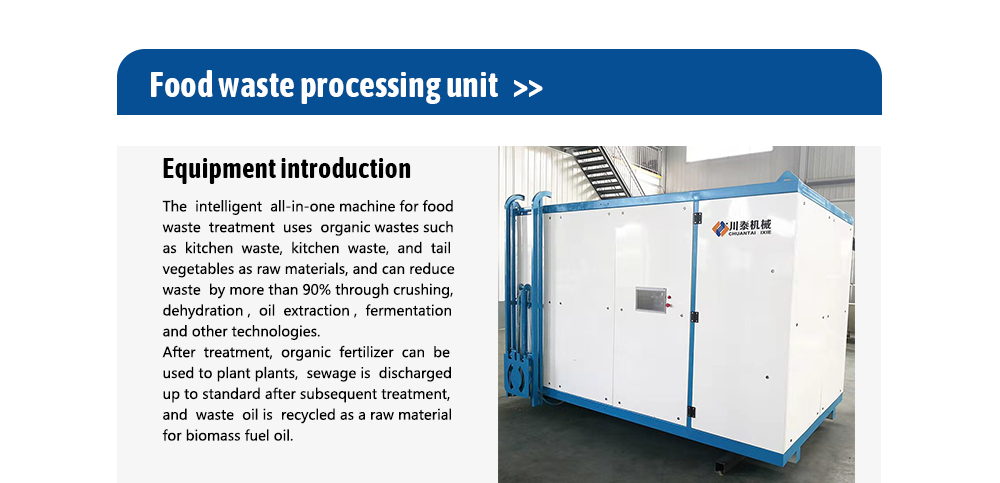

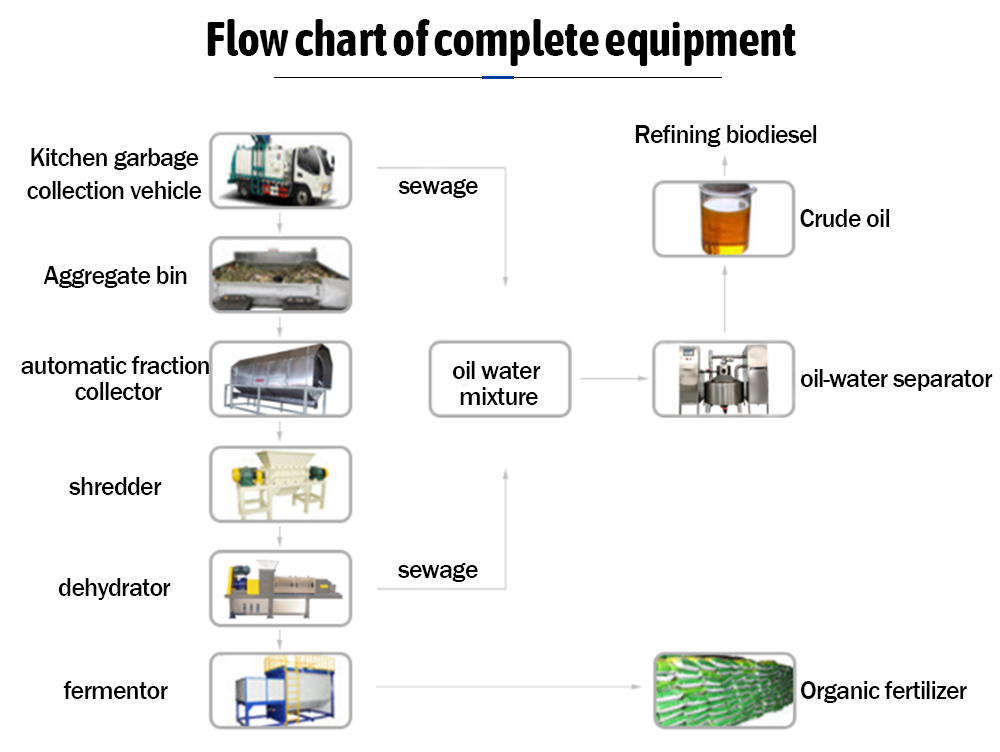

Equipment Introduction The kitchen waste intelligent integrated machine uses organic waste such as kitchen waste and food waste as raw materials. Through techniques such as crushing, dehydration, oil extraction, and biological fermentation, the machine can reduce waste by 75% to 90%. The equipment includes functions such as human-machine interaction intelligence, automatic weighing and lifting, sorting, pressing and dehydrating, oil-water separation, spiral lifting, aerobic fermentation, and exhaust gas treatment. The waste oil and fat recovered after treatment can be used as raw materials for biomass fuel, and the solid organic matter can be used as raw materials for organic fertilizer.

1.Source reduction The kitchen waste and food waste have high organic content and are prone to decay. By using "biological harmless treatment technology" for on-site treatment, the organic waste can be harmlessly treated at the source.

2.Reduce environmental pollution Controlling pollutants from the source can avoid environmental pollution caused by littering, scattering, dripping, and leaking during collection and transportation. This processing method is a closed system, which does not cause pollution to the surrounding environment.

3.Turning waste into treasure After oil and water separation, the oil can be sold, and the solid waste residue can be made into highly efficient organic fertilizer through aerobic fermentation, both of which have high economic value.

4.Big data function It can achieve online monitoring, big data, IoT and other functions, and provide data support for management.

5.Low energy consumption The whole machine adopts energy-saving and consumption-reducing design: optimized electrical design, linear control, comprehensive insulation, high heating efficiency, heat recovery utilization, and reduced operating costs.

6.Low maintenance cost The whole machine is composed of standard parts, modular components and equipment units, which are scientifically reasonable and easy for "mass production, installation, disassembly, use, maintenance and upkeep".

Number | Item | Name | Parameter |

1 | Basic Parameters | Model | CT-YTJ-3 |

Daily Processing Capacity | 1-3T | ||

Reduction Rate | 70-95% | ||

Total Power | 98KW(adjustable) | ||

Warranty | 12 months from factory | ||

Data Monitoring | Manual, Automatic, Remote Control | ||

2 | Pretreatment System | Automatic Lifting | 380V 2.2KW |

Weighing System | |||

Sorting Platform | 0.75KW | ||

Crushing System | 5.5KW | ||

Pressing System | 7.5KW | ||

Oil-water Separation System | 24KW | ||

3 | Biochemical System | Mixing System | 15KW |

Auxiliary Heating System | 36KW | ||

Control Method | Automatic, Manual | ||

Discharge | Automatic | ||

4 | Waste Gas System | Spraying Tower | 1.5KW |

Activated Carbon Box | |||

Negative Pressure System | 5.5KW |

If your company wants to establish a business relationship with us, please briefly describe the cooperation intention and send an email to:chuantaiscrewpress@gmail.com