Application advantages of screw press dehydrator:

1. The screw press dehydrator is widely used, with high production efficiency, large processing capacity, strong dehydration ability, and low moisture content of slag cake

2. The body of the equipment is made of 304 stainless steel, which has good corrosion resistance and acid resistance, and the equipment has a long service life.

3. The machine is a fully enclosed structure, the juice does not overflow, the material is not polluted, the quality is improved, and the working environment is improved.

4. After the material to be processed is fed from the feed port, it is squeezed and crushed by the spiral blade, and is transported forward with the screw, and sent out from the discharge port.

5. Such as plant rhizomes, roots, such as dehydration of corn stalks.

6. Manure industry, pig, cattle, chicken and various livestock and poultry manure solid-liquid separation biogas and bioethanol before and after solid-liquid separation.

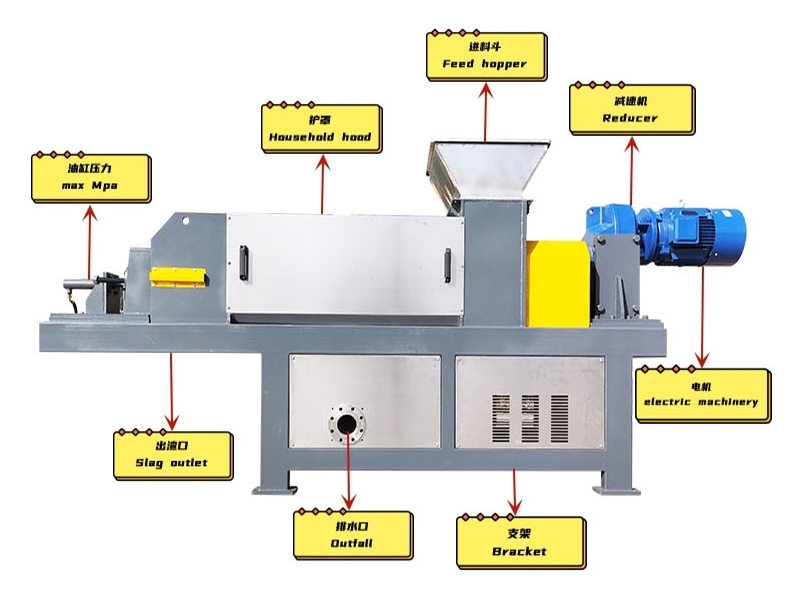

The working principle of the screw press dehydrator is to push the material forward through the screw, and then reduce the volume of the screw cavity to squeeze out the juice in the material. It is the supporting facilities and mechanical equipment of the trash grid, which is composed of a feed hopper, an extrusion screw, a spiral steel pipe, a slag discharge pipe and driving equipment. The grid residue or filtered filter residue obtained by the grille enters the spiral steel pipe from the feed hopper, and is extruded and dehydrated under the action of the extruding screw. The water permeable screen extruded from the raw material collects in the sink and is discharged through the drain. After the raw materials are shrunk, they are discharged through the slag discharge pipe, which can greatly reduce the weight and volume of scale slag and other dirt. The screw press machine is composed of drain pipe area, feeding area, screw conveying area and feeding area. The grid slag enters the material area, and is compacted in the compaction area by the screw press, the grid slag is discharged, and the sewage is injected into the water collection pipe from the grid bar. This equipment is suitable for juicing apples, seabuckthorns, cucumbers and other fruits and vegetables.

The specific operation steps of the screw press dehydrator:

1. Before feeding the screw press dehydrator, the cone and the feeding port should be closed, and the pressure spring torque should be adjusted appropriately according to the nut. When the slag skin produces slag resistance, check the actual effect of squeezing, and then properly adjust the clamping capacity and position of the spring to achieve a satisfactory squeezing effect.

2. When feeding the screw press dehydrator, prevent dirt and other objects from entering the equipment. Thicker branches should be removed to prevent damage to the screen drum. The feeding should be as uniform as possible to make the actual effect better.

3. The screw press dehydrator relieves the pressure spring in advance, so that the cone moves under the promotion of pomace. The pomace in the back is too compact to facilitate removal. When not in use for a long time, the equipment should be cleaned and greased on the rust-prone parts for maintenance.

The maximum design parameters of the screw press dehydrator are the parameter values related to the material characteristics, which are the key to realize the cooperation between man and machine.

If your company wants to establish a business relationship with us, please briefly describe the cooperation intention and send an email to:chuantaiscrewpress@gmail.com

![[list:title]](/static/upload/image/20240528/1716877114510915.jpg)