Industrial hemp, a versatile and sustainable crop, has gained significant attention for its various applications, including textiles, paper, construction materials, and more. The extraction of hemp fibers is a crucial step in harnessing the plant's potential for industrial use. In recent years, the development of advanced hemp fiber extraction machines has played a pivotal role in streamlining and enhancing the efficiency of this process.

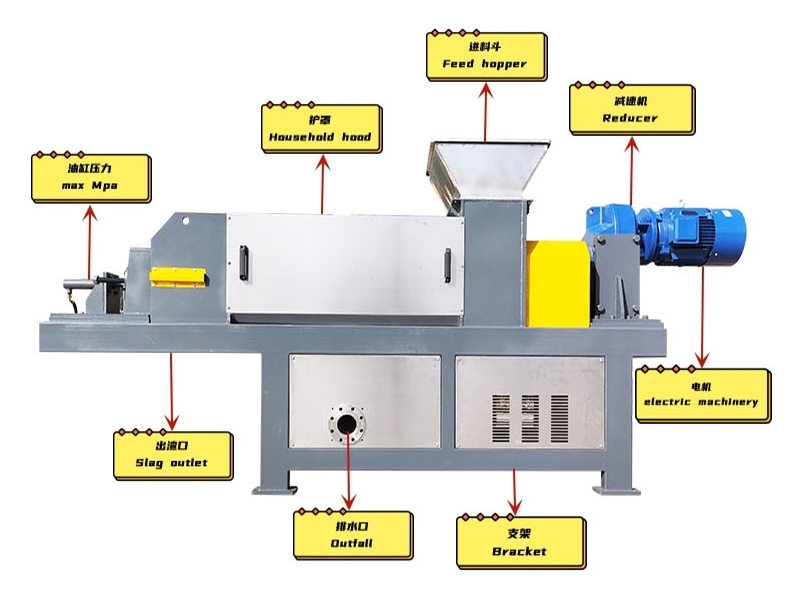

Key Features of Hemp Fiber Extraction Machines:

Automated Processing:

Modern hemp fiber extraction machines are equipped with automated systems that reduce manual labor and increase overall efficiency. These systems handle tasks such as feeding, separation, and collection, ensuring a seamless extraction process.

High Throughput:

The demand for hemp fibers in various industries necessitates high-throughput extraction machines. State-of-the-art equipment is designed to process large quantities of hemp plants, meeting the growing industrial needs for sustainable raw materials.

Gentle Extraction Techniques:

To preserve the quality of hemp fibers, extraction machines utilize gentle processes that minimize damage to the fibers during the separation from the plant. This is crucial for maintaining the integrity of the fibers for use in textiles and other applications.

Versatility in Fiber Length:

Different industries require hemp fibers of varying lengths for specific applications. Advanced extraction machines offer adjustable settings to cater to the diverse needs of end-users, providing flexibility in the length of extracted fibers.

Efficient Cleaning Mechanisms:

Hemp fibers are often surrounded by hurd, a woody inner core of the hemp stalk. Extraction machines incorporate efficient cleaning mechanisms to separate the fibers from the hurd effectively. This results in high-quality fibers ready for further processing.

Energy-Efficient Designs:

Sustainability is a key consideration in industrial processes. Many modern hemp fiber extraction machines are designed with energy efficiency in mind, incorporating features such as low power consumption and optimized processing cycles.

Quality Control Systems:

Quality control is paramount in ensuring the final product meets industry standards. Hemp fiber extraction machines often include built-in quality control systems that monitor the extraction process, allowing for adjustments in real-time to maintain consistent fiber quality.

Conclusion:

The development and integration of advanced hemp fiber extraction machines have significantly contributed to the efficiency and sustainability of industrial hemp processing. These machines not only streamline the extraction process but also support the growing demand for eco-friendly alternatives in various industries. As technology continues to evolve, further innovations in hemp fiber extraction machinery are expected, driving the industry towards even greater levels of efficiency and environmental responsibility.

If your company wants to establish a business relationship with us, please briefly describe the cooperation intention and send an email to:chuantaiscrewpress@gmail.com

![[list:title]](/static/upload/image/20240528/1716877114510915.jpg)