Screw press dehydrator

Screw press dehydrator is a kind of equipment commonly used for solid-liquid separation. Its structure is complex and delicate, and it can efficiently separate solid particles from liquid. It is widely used in agriculture, food processing, environmental protection and other fields. This article will introduce the structure and working principle of the screw press dehydrator in detail.

1. Structural composition

The structure of the screw press dehydrator mainly includes the following parts:

1. Feeding system: The feeding system is responsible for introducing the mixture containing solid particles and liquid into the equipment. It usually includes components such as feed hopper, feeding screw, etc., to ensure that the mixture is evenly distributed to the screw pressing area.

2. Screw press area: The screw press area is a key part of the dehydration process. It consists of one or more helices, usually surrounded by a screen or strainer, which are used to block the passage of solid particles and allow liquids to flow out. The rotation of the spiral pushes the mixture forward gradually, and at the same time exerts pressure, so that the solid particles are gradually squeezed and dehydrated.

3. Slag discharge system: The slag discharge system is used to send the extruded solid particles out of the equipment. It usually includes a slag discharge port, a slag discharge screw, etc., to ensure that the dehydrated solid particles can be removed in time.

4. Liquid flow collection system: The liquid flow collection system is responsible for collecting the liquid flowing out from the screw press area. It is usually composed of a sump, a liquid flow pipe, etc., and guides the separated liquid to a designated collection container.

5. Transmission system: The transmission system drives the rotation of the screw through the motor, reducer and other components to realize the pressing effect in the dehydration process.

2. Working principle

The working principle of the screw press dehydrator is based on the principle of solid-liquid separation, and its main steps are as follows:

Mixture feeding: The mixture containing solid particles and liquid is introduced into the screw press through the feeding system.

1. Press dehydration: The rotation of the screw pushes the mixture to move forward gradually in the screw press area. During this process, as the pitch of the screw gradually decreases, the space also gradually shrinks, so that the solid particles are squeezed and squeezed, thereby releasing excess liquid.

2. Solid-liquid separation: In the screw press area, the solid particles are squeezed and dehydrated, while the liquid gradually seeps out through the screen or strainer. The solid particles are pushed to the slag outlet of the equipment along the direction of spiral movement.

3. Slag discharge and liquid discharge: the dehydrated solid particles are discharged from the equipment through the slag discharge system, and the dehydrated liquid is guided to the collection container by the liquid flow collection system.

4. Circulation operation: The screw press dehydrator can work continuously, and through continuous circulation operation, an efficient solid-liquid separation process can be realized.

in conclusion

As an important solid-liquid separation equipment, the screw press dehydrator plays an important role in various fields. Its complex and delicate structure and scientific working principle enable it to efficiently separate solid particles from liquid, providing strong support for production in various industries. Through continuous technological innovation and optimization, the screw press dehydrator will have a broader development prospect in the future application.

If your company wants to establish a business relationship with us, please briefly describe the cooperation intention and send an email to:chuantaiscrewpress@gmail.com

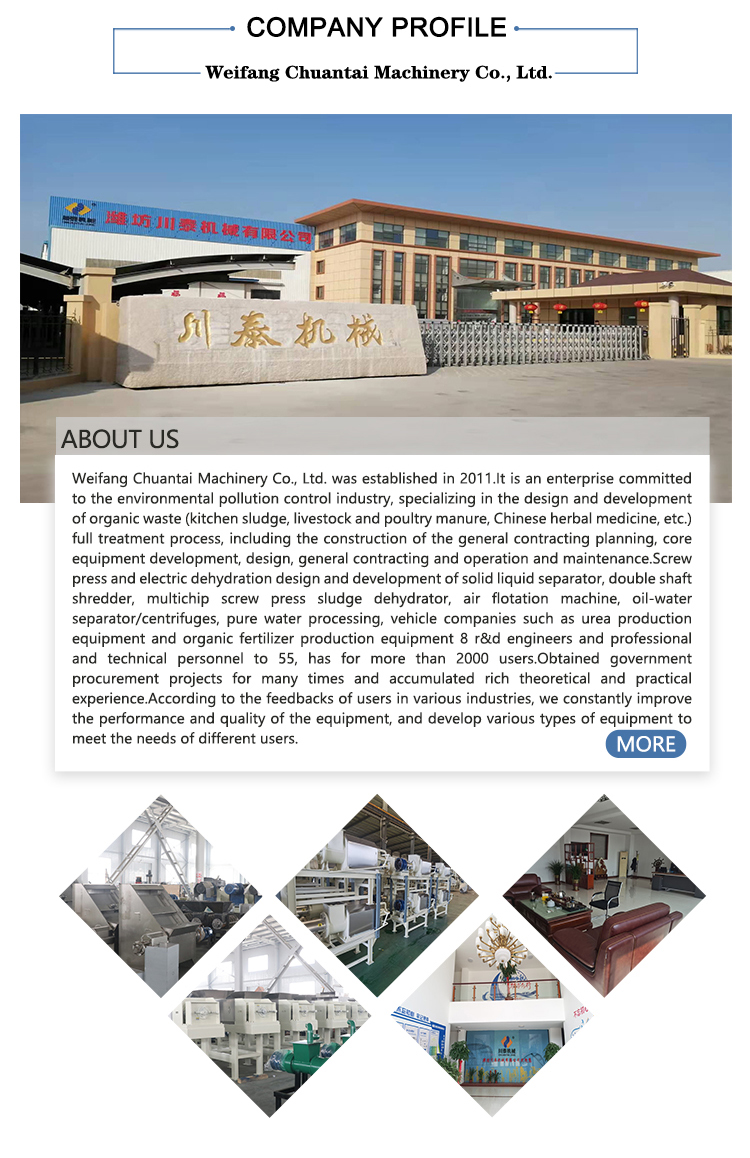

![[list:title]](/static/upload/image/20240528/1716877114510915.jpg)