Precautions for cow dung solid-liquid separator in operation:

1. There is no abnormal noise under the premise of no-load operation of the cow dung solid-liquid separator, the movements of all parts are coordinated, and the fasteners are not loose;

2. Try not to run under load. Even if you need to run under load to catch up with work, you must ensure that there is no abnormal noise, and you must ensure that the noise differential pressure level is not greater than 85db(A).

3. Check whether the overall casing of the cow dung solid-liquid separator is neatly installed, square, and the edges of the exposed joint surface are neat. , sharp edges and other defects.

4. Check whether the discharge is normal and whether there is any leakage.

Installation method of cow dung solid-liquid separator:

The first step is to install the steel wire pipe, install the steel wire pipe on the street host, and use the steel pipe to block it to avoid falling off.

The second step is to install the feed pipe on the hydraulic pump at the other end of the cow dung solid-liquid separator, and then connect the drain pipe, that is, the pipe is installed.

The third step is to connect the electricity. When the solid-liquid separator is connected to electricity, the main power switch must be turned off. When connecting cables, pay attention to the color of the cables. Different colors correspond to different parts of the power cord (red is the external power supply, blue is the host power supply, yellow is the water pump power supply)

The fourth step is to adjust the counterweight iron. Adjusting the position of the counterweight iron can adjust the dry humidity of the dry and wet partitions.

The fifth step is to be familiar with the function of each button on the operation panel of the cow dung solid-liquid separator for easy operation.

The sixth step is to test run the cow dung solid-liquid separator to see if the dry humidity of the separated particles is up to standard.

The effect of the cow dung solid-liquid separator:

1) The capacity of the farmer’s old biogas digester was too small, and the time for the sewage to enter the pond was too short, resulting in a high concentration of wastewater. Therefore, before the waste water enters the pond, the livestock and poultry manure solid-liquid separator is used for treatment, which can effectively reduce the waste water COD, BOD content, reduce the operating load of the biogas digester, thereby simplifying sewage discharge;

2) The feces in the fresh sewage can be converted into valuable fish feed or organic fertilizer by using the solid-liquid separator. The separated waste water enters the biogas digester intermittently, so that the anaerobic pond has sufficient digestion time, so that the active bacteria in the pond can reproduce more vigorously and produce higher gas production. The methane content of the gas is naturally high, and the high purity of the gas naturally solves the problem of abnormal operation of the biogas generator;

3) The wastewater treated by the solid-liquid separator enters the biogas digester. It can effectively deal with the incrustation phenomenon of biogas digesters and avoid the cleaning of biogas residues.

If your company wants to establish a business relationship with us, please briefly describe the cooperation intention and send an email to:chuantaiscrewpress@gmail.com

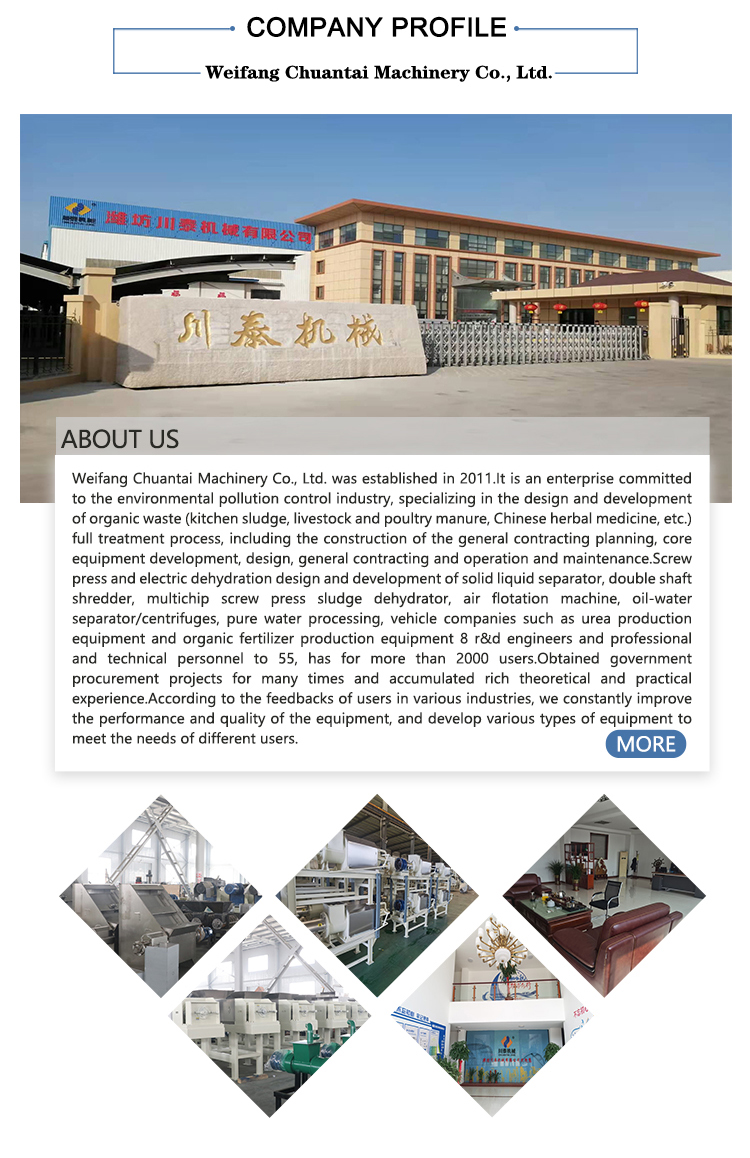

![[list:title]](/static/upload/image/20240528/1716877114510915.jpg)