Screw press dewatering machines are essential tools in various industries for the efficient separation of liquid and solid components in waste materials. These machines are widely used in wastewater treatment, food processing, pulp and paper production, and other industries where dewatering of slurry or sludge is required.

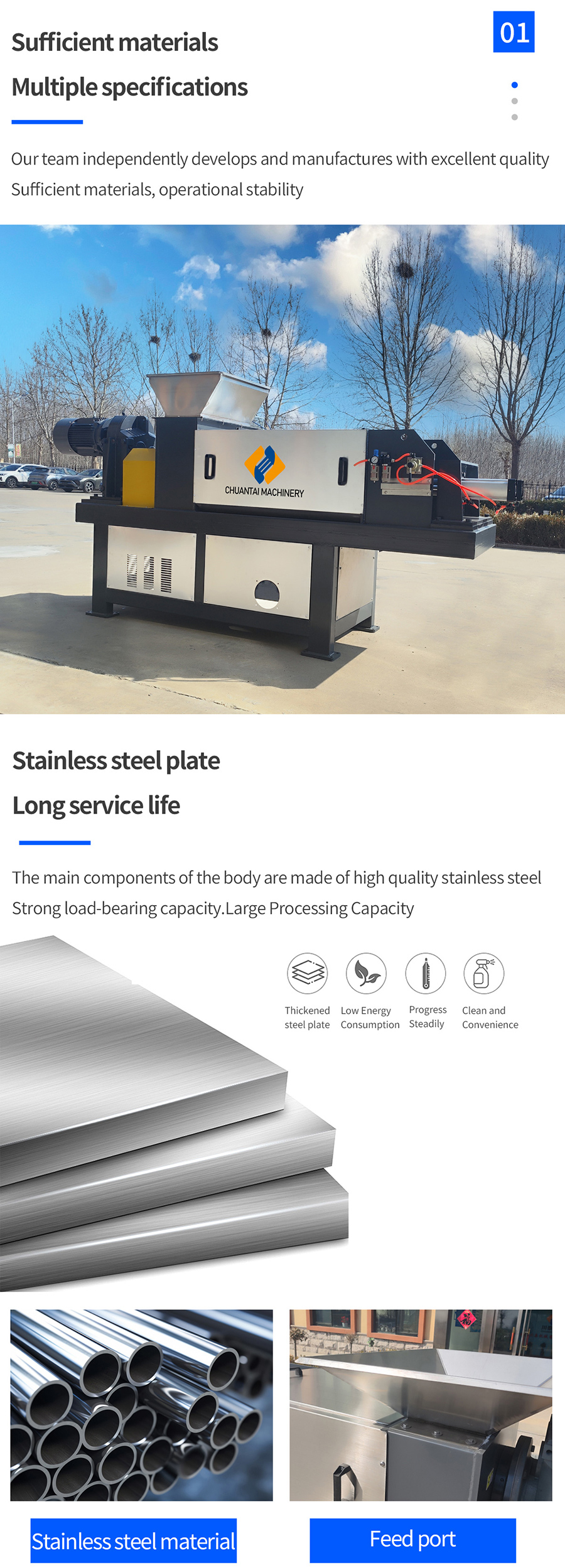

The screw press dewatering machine operates on a simple yet effective principle. It consists of a cylindrical screen and a screw conveyor inside it. The slurry or sludge is fed into the machine, where the screw conveyor rotates slowly, pushing the material towards the discharge end. As the material moves along the length of the screw, the pressure increases, and the liquid is forced out through the screen, leaving the solid fraction to be discharged at the end.

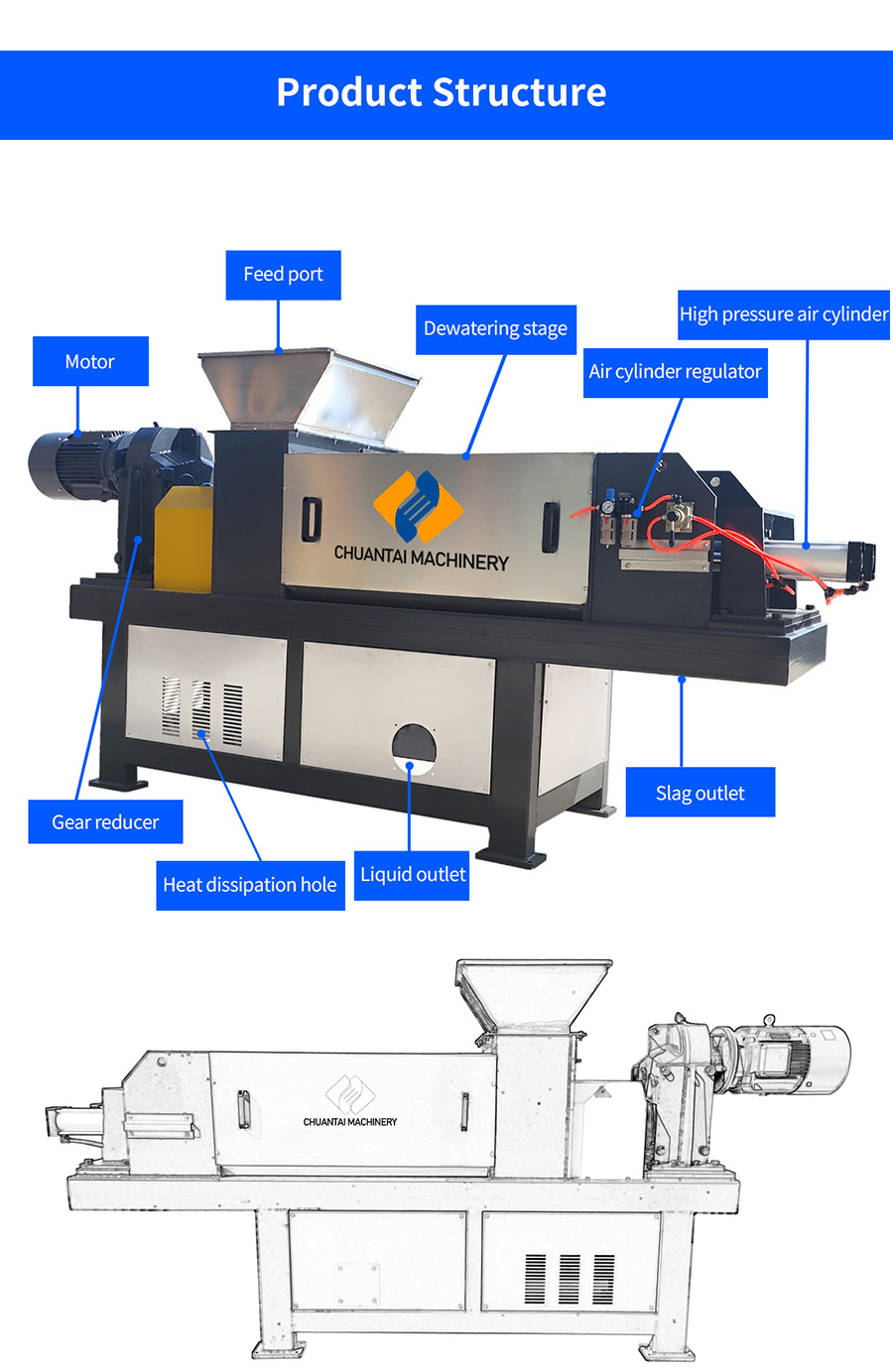

Feed Hopper: The entry point for the slurry or sludge into the machine.

Screw Conveyor: A helical screw that transports and compresses the material.

Cylindrical Screen: A perforated or mesh cylinder that allows liquid to pass through while retaining solids.

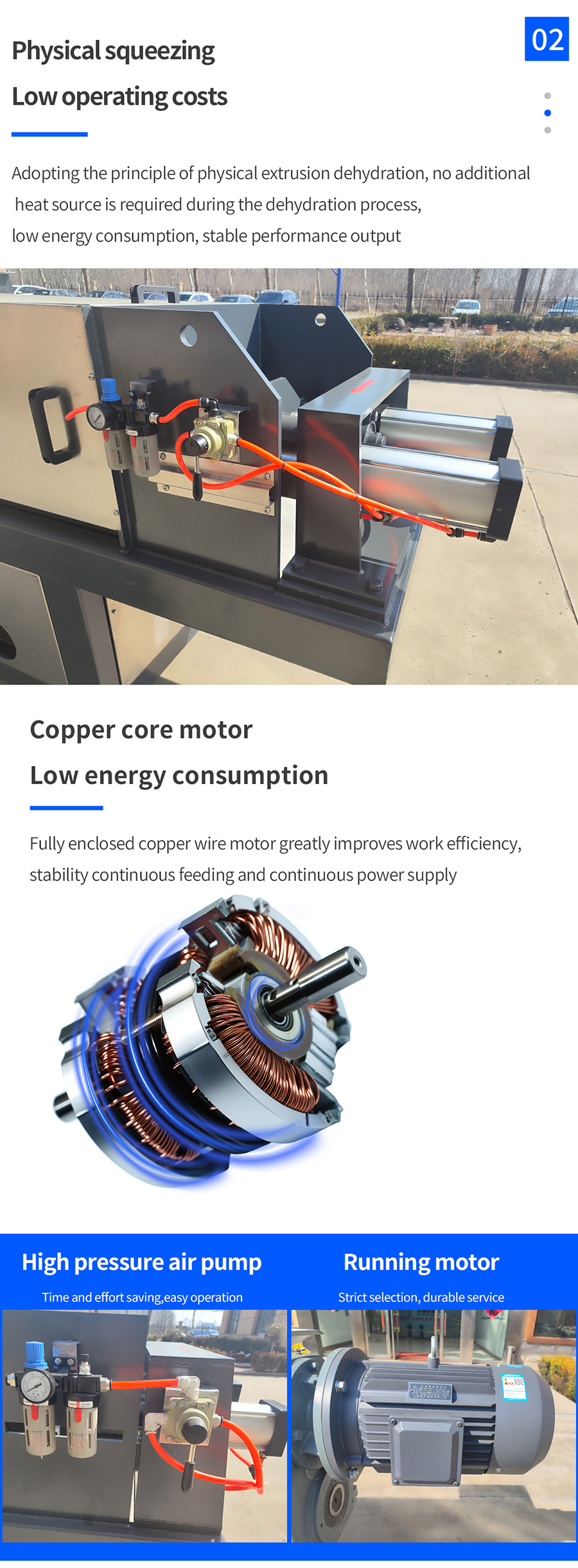

Drive Motor: Powers the screw conveyor to rotate.

Discharge Outlet: The exit point for the dewatered solids.

Filtrate Outlet: The exit point for the separated liquid.

Efficient Dewatering: Screw press machines provide high levels of dewatering efficiency, producing dry solids and reducing the volume of waste.

Energy Efficient: These machines typically consume less energy compared to other dewatering methods, making them cost-effective.

Low Maintenance: With fewer moving parts and robust construction, screw press machines require minimal maintenance.

Continuous Operation: Designed for continuous operation, they can handle large volumes of material without interruption.

Versatility: Suitable for a wide range of applications, from municipal wastewater treatment to industrial sludge management.

Municipal Wastewater Treatment: Used to dewater sludge from sewage treatment plants.

Food Processing: Effective in separating liquid from food waste or by-products.

Pulp and Paper Industry: Utilized for dewatering paper pulp and other fibrous materials.

Agricultural Waste: Helps in managing animal manure and other agricultural by-products.

Chemical Industry: Applied in the separation of liquid from chemical sludge and other industrial processes.

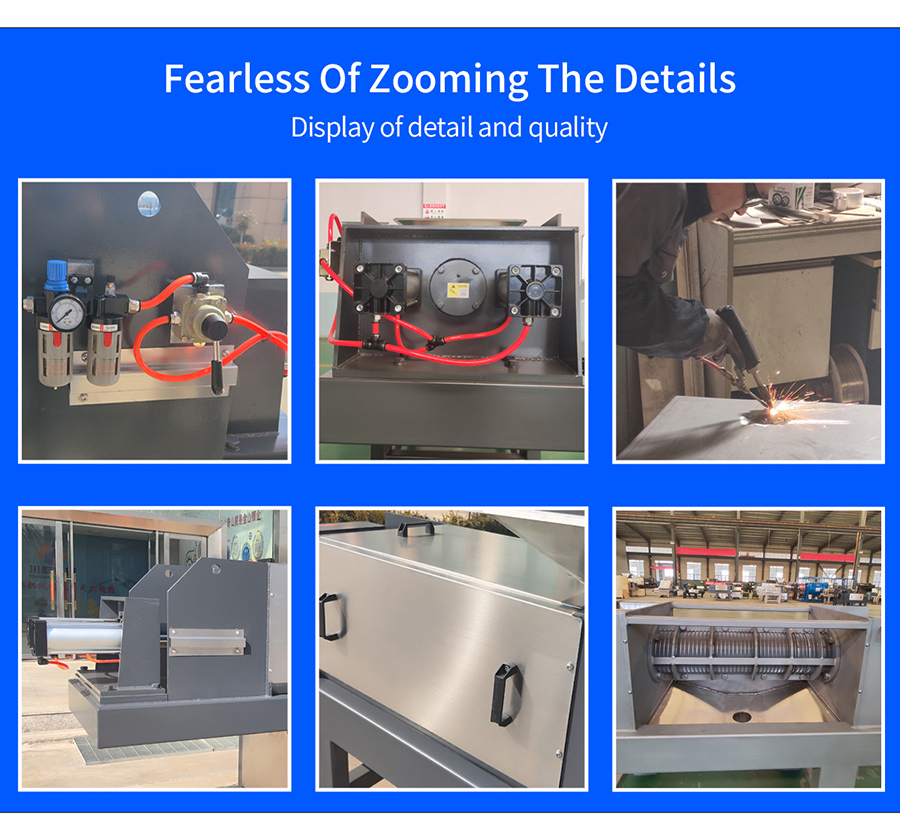

Regular Inspection: Periodically check the machine for wear and tear, especially the screw and screen.

Lubrication: Ensure that the moving parts are properly lubricated to reduce friction and wear.

Cleaning: Keep the screen and other components clean to maintain efficiency.

Monitoring: Keep an eye on the machine’s performance parameters and address any anomalies promptly.

Spare Parts: Keep essential spare parts on hand to minimize downtime in case of component failure.

Screw press dewatering machines are vital in the efficient management of waste materials across various industries. Their ability to separate liquids from solids effectively, combined with low energy consumption and maintenance requirements, makes them an invaluable asset in modern waste management and processing operations. Investing in a high-quality screw press dewatering machine can lead to significant cost savings and operational efficiency improvements.

If your company wants to establish a business relationship with us, please briefly describe the cooperation intention and send an email to:chuantaiscrewpress@gmail.com