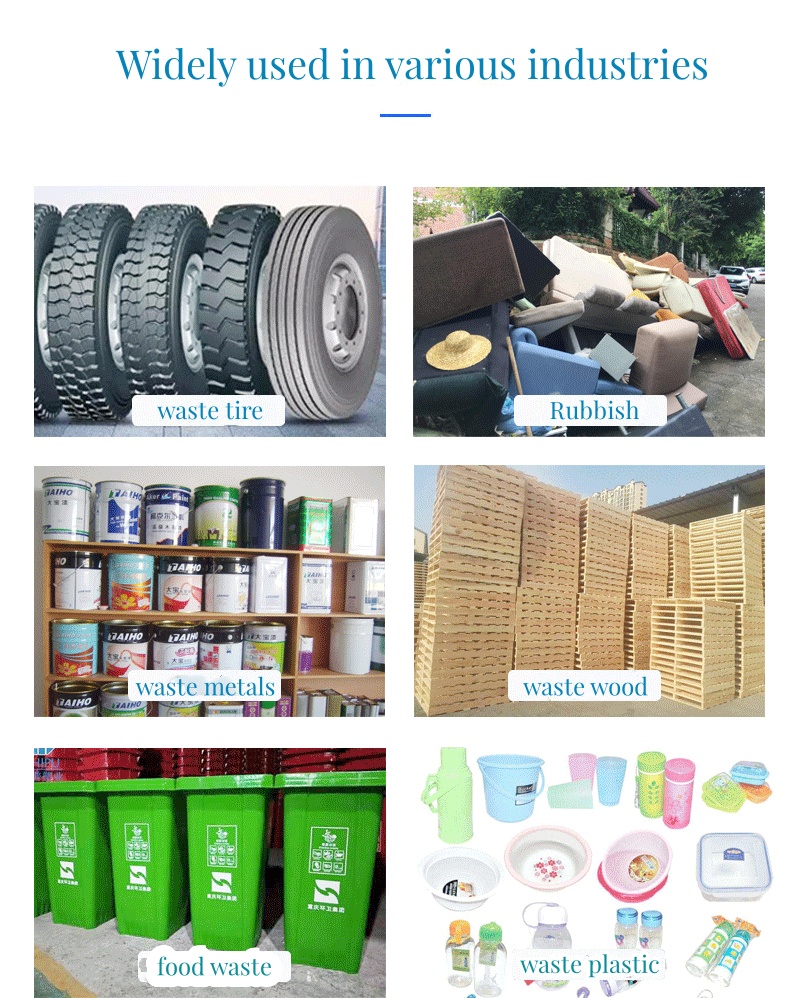

The double-shaft shredder is widely used in food waste, household waste, waste plastics, wood, tires, metal, home appliances and other related solid waste utilization fields.

The modular design of the whole machine, according to different material characteristics and production capacity requirements, configure the corresponding tooth structure, cutter body arrangement, cutter material and box size.

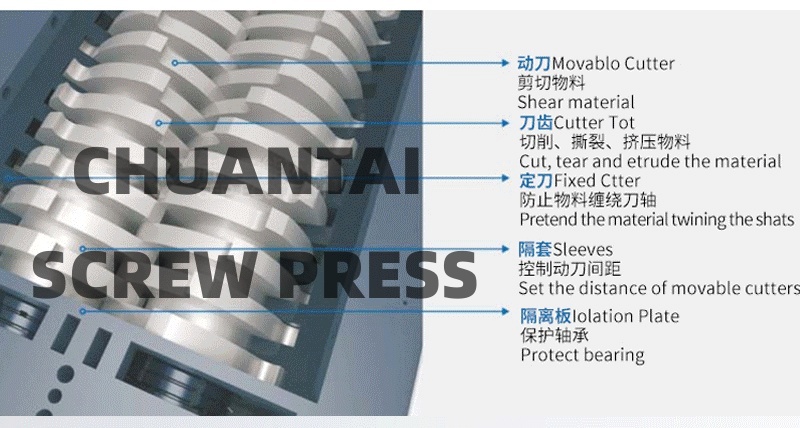

Structural composition of double shaft shredder:

1. The main body of the shredder: the main body of the equipment is welded with high-quality steel plate to eliminate stress treatment / integral machining to ensure the stability of the equipment under heavy load for a long time;

2. Bearing and seal: The bearing seat adopts the patented joint and detachable type, which can quickly remove the moving knife, fixed knife, bearing and other components, and is easy to maintain and replace the knife. The unique sealing structure effectively blocks the contact of broken objects and grease, and handles Liquid materials can also protect bearings and gears, etc.;

3. Moving knife and fixed knife: The material of the moving knife is made of forged blank of special alloy tool steel, precision machining, multiple heat treatment and low temperature freezing heat treatment technology. The overall toughness and hardness are consistent and can be repaired and used repeatedly to ensure cutting performance and service life. The fixed knife adopts the patented hook installation, which optimizes the tool replacement function and makes the tool maintenance and replacement more efficient;

4. Cutter shaft: It is processed and refined with high-strength and heavy-duty special steel, and it is more reasonable to cooperate with the cutter to provide powerful cutting power.

If your company wants to establish a business relationship with us, please briefly describe the cooperation intention and send an email to:chuantaiscrewpress@gmail.com